The Commonwealth Center for Advanced Manufacturing (CCAM), in partnership with Siemens, the University of Virginia, Virginia State University, and Oak Ridge National Laboratory (ORNL), has successfully completed a research initiative focused on integrated process and materials modeling for additive manufacturing (AM) of refractory materials. This project represents a step forward in the development of advanced process control strategies for high-performance materials used in critical applications such as gas turbine energy generation.

The Challenge: Manufacturing High-Temperature Refractory Metals

As energy demands evolve, the need for materials capable of withstanding prolonged operating temperatures of 1300°C has become increasingly urgent. Refractory metals, including niobium (Nb), molybdenum (Mo), tungsten (W), and tantalum (Ta), are prime candidates due to their exceptionally high melting points—typically exceeding 2500°C. Traditionally, these materials have been fabricated using powder metallurgy (PM) due to the challenges of conventional casting techniques. However, AM presents a promising alternative with key advantages:

- Shorter lead times

- Enhanced design flexibility

- Reduced material waste and cost savings

Project Goals and Approach

This project aimed to leverage integrated AM simulations to develop and confirm the process relationships for advanced process control of C103, a high-performance niobium-based alloy. CCAM and ORNL collaborated to apply high-performance computing (HPC) to model and optimize the powder direct energy deposition (DED) process.

The research team focused on:

- Developing high-fidelity computational fluid dynamics (CFD) melt pool simulations for C103

- Simulating and validating multi-physics interactions between the heat source, material, and manufacturing parameters

- Establishing process maps for defect detection (porosity) and geometric precision (surface roughness)

CCAM contributed its expertise in experimental DED processing, generating key datasets that helped refine the Star-CCM+ multi-physics simulations. ORNL and the National Renewable Energy Laboratory (NREL) provided the computational power necessary to model melt pool behavior at a high level of accuracy.

Key Achievements

The project successfully delivered critical advancements in AM process modeling, including:

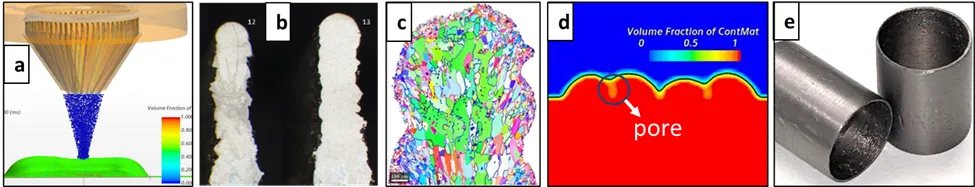

- Validated CFD Melt Pool Simulation – The team developed an advanced CFD melt pool model for C103, ensuring its accuracy in predicting scan speed, laser power, and hatch spacing through experimental validation.

- Process Mapping for Quality Optimization – Simulations and experiments led to the creation of defect detection and geometric precision maps, identifying optimal process parameters for minimizing porosity and controlling surface roughness.

- Microstructure Simulation – Linking melt pool dynamics to grain morphology predictions allowed for precise microstructure characterization under defect-free conditions.

- Enhanced AM Process Control – The study demonstrated that hatch spacing adjustments can significantly impact build efficiency and surface finish, guiding future process optimization strategies.

Figure 1. a) DED model; b) Multi-layer trials; c) EBSD imaging; d) Porosity model; e) Machined coupons made from C103 DED tubes.

Impact and Future Applications

This research aligns with a broader computational modeling framework aimed at enabling virtual process design and part quality certification for refractory alloys. The CFD melt pool simulation developed in this project has the potential to be integrated into in-situ sensing systems, enabling real-time monitoring and closed-loop control of the DED process.

By optimizing AM parameters and tool path strategies, this project reduces design lead times, minimizes material waste, and enhances production efficiency. Ultimately, these advancements position CCAM and its partners at the forefront of additive manufacturing innovation for high-performance materials.

A Collaborative Step Toward the Future of AM

This initiative underscores CCAM’s commitment to bridging industry, academia, and national labs to drive cutting-edge manufacturing solutions. The successful integration of AM process simulations, experimental validation, and computational modeling in this project sets a new standard for developing next-generation refractory materials for energy and aerospace applications.

As we continue to push the boundaries of additive manufacturing capabilities, CCAM remains dedicated to fostering collaborative innovation and delivering high-value technological advancements to our members and the broader manufacturing community.

Interested in learning more?

Stay connected with CCAM for updates on future research initiatives, workshops, and collaboration opportunities!