At CCAM, we seek to ensure that students learn ways to leverage technology to improve quality, productivity, and outcomes. Today, we are excited to highlight Antonio R. Carrington Jr., a National Science Foundation (NSF)-sponsored CCAM Graduate Research Assistant, whose contributions are advancing CCAM’s research in additive manufacturing.

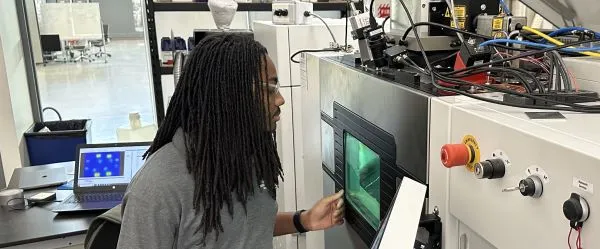

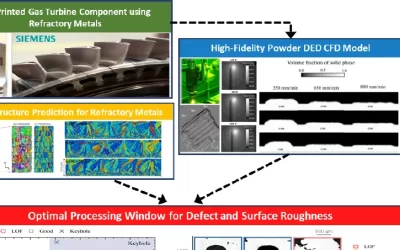

Antonio is a second-year Ph.D. student in Industrial and Systems Engineering at Virginia Tech. He previously earned his B.S. in Manufacturing Engineering from Virginia State University in 2023. His current research, conducted in the Laboratory for Advanced Manufacturing Processes and Sensing (LAMPS) under the guidance of Dr. Prahalada Rao, focuses on thermal modeling of additively manufactured parts created with Laser Powder Bed Fusion (LPBF) and Wire Arc Additive Manufacturing (WAAM). Antonio has also developed extensive expertise in metallurgical analysis, utilizing techniques such as microhardness testing, scanning electron microscopy, and X-ray CT scanning to assess material properties.

Antonio’s work at CCAM is made possible by the NSF INTERN program, a supplement to Dr. Rao’s NSF Partnerships for Innovation (PFI) Program award. This funding has supported his tuition, stipend, and travel expenses, allowing him to gain valuable industry experience while continuing his academic studies. His time at CCAM is providing him with access to experienced researchers and cutting-edge projects, creating the ideal environment for both advancing his research and developing new technical skills.

Antonio’s journey with CCAM began before his Ph.D. studies—he previously served as an undergraduate Intern at CCAM for two different sessions, demonstrating his early dedication to the field of advanced manufacturing. Now, as a Graduate Research Assistant, he is leveraging his expertise to assist industry partners in selecting the best LPBF modeling tools, leading the development of a machine learning model to predict flaws in complex LPBF geometries, and supporting another model aimed at predicting microstructure evolution in LPBF-manufactured parts. His understanding of thermal modeling, data analysis, and sensor integration makes him a valuable asset to CCAM’s research efforts.

We are proud to have Antonio as part of our research team and look forward to seeing his continued success in the field of additive manufacturing!